Rotor Blade Design

Introduction

In the section Rotor Aerodynamics we considered

the aerodynamic aspects of airfoils. We will, therefore, now look at several rotorblade designs.

Airfoil, lift and drag

Probably the single most important rotor design parameter is its Lift/Drag

ratio, which should be as high as possible.

This ratio depends on the design of the aerofoil , and before we go on to discuss a number of types, we will first introduce the fineness ratio. This is the thickness of the airfoil as a percentage of the chord length. A blade with a good L/D performance

has a fineness ratio of about 15%, with its maximum

chamber being a quarter of the way back from the leading edge. A typical L/D value for a helicopter

blade is 30:1.

, and before we go on to discuss a number of types, we will first introduce the fineness ratio. This is the thickness of the airfoil as a percentage of the chord length. A blade with a good L/D performance

has a fineness ratio of about 15%, with its maximum

chamber being a quarter of the way back from the leading edge. A typical L/D value for a helicopter

blade is 30:1.

The types of aerofoils used with a rotorblade differ (figure below). For a long time, most of them

were symmetrical. However, a higher L/D ratio is possible with

non-symmetrical versions. Due to the greater internal forces occurring in these

types of blades, they

only came into existence when the appropriate composite materials

were developed. These

can cope with the high internal strain, while their weight

is kept low.

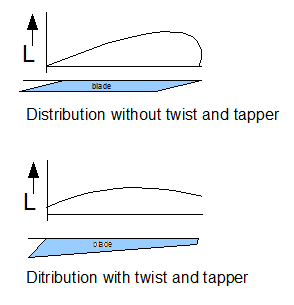

Blade twist and tapper

When a blade rotates, each point on it travels at a different speed. The

further away from the root, the higher the velocity. This means that the

contribution to lift and drag of every point on the blade differs, with each aspect getting larger

when moving closer to the rotor tip. Clearly, the lift distribution

over the blade is not constant. This is not a desirable situation, because the contribution diminishes

when getting closer to the root.

To change this distribution, blades

are twisted and, sometimes, also tapered. The twist is such that the angle of attack increases

when travelling towards the root, producing more lift. Tapering the blade also contributes

to achieving a more evenly spaced lift distribution. With

blade tapering, the blade's

surface gets larger when travelling towards its root.

Both tapering and twisting

can be observed when looking carefully at rotorblades

at rest. Note that blade tapering

is not always used (especially on metal blades because of a more complicated fabrication process).

Blade root cut out

Blade twist and taper leads to large angles of attack and large blade surfaces

at the root. However, close to the root, the blade is travelling over the hull, so

the

generated downwash does not contribute to helicopter thrust. For this reason,

rotorblades are often cut out near the root. Another reason for rotor blade cut out is

to reduce the effects of potential reverse flow (on the retreating rotorblade)

when flying at high speeds.

Twisting moments

Rotorblades are constantly strained by moments that try to twist them. This twisting

has its origins in the moments which exist between the centre of pressure (due to

the aerodynamic forces) and the mass centroid over the chord line.

The blade designer must take these twisting moments into account by designing a

blade with high torsional stiffness. He must also ensure that the mass centroid is

located ahead of the centre

of pressure for all blade angles (in its operational range). In this way, lift tends to lower the angle of attack: a stable condition.

Blade tip speed and noise reduction

When the blades are very long or the helicopter is designed with a high rotor RPM,

the blade tip speed can become extremely high. When the tip speed reaches the sound of speed,

pressure waves come into existence, which causes rotor drag. A high tip speed is also

the single most important design parameter influencing generated noise levels.

It is, therefore, logical to expect more designs with lower RPM and very efficient

(larger L/D ratio) performance blades. In this way, blade efficiency is traded off for noise

reduction instead of better flight performance.

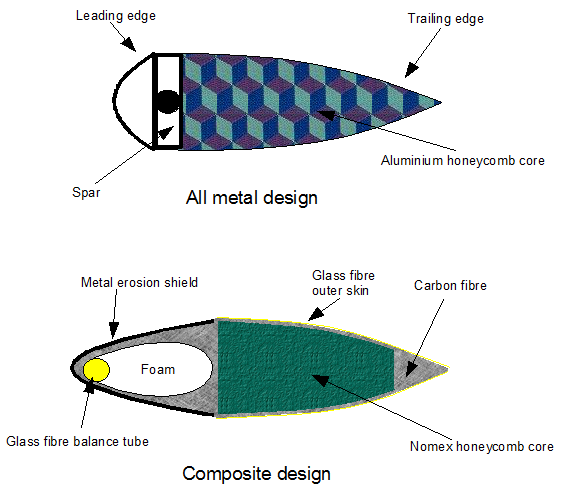

Construction

Some important design requirements for blades are high torsional stiffness and

a good L/D ratio. Note that the weight of the rotor also has important consequences

for both the necessary engine power and stored kinethic energy (important for good auto-rotation

performance).

The early designs of rotorblades, which resemble early

classic wing design, consisted of long steel tube spars, wooden ribs

and some light surface material attached to them. From the 1960s onwards, all metal aluminium alloy blades were introduced.

These were constructed from long hollow leading edge D-spar extrusions, allied with

some light (probably aluminium) trailing edge constructions. The use of extrusions

made blade taper difficult to produce. Honeycomb constructions were added to achieve

a stiff and light construction.

These days, composite materials like fibreglass and carbon fibre are used for the

fabrication of rotorblades. Stainless steel leading edge spars are also used, and

all composite

spar designs exist too. The fatigue life properties of composite materials are far

better than those of metals. Fibreglass is used for its strength and chemical inertness.

Carbon fibre layers, sandwiched at right angles, are used to add stiffness. A sample design might look like the figure below. Generally, composite blades also

have some extra added weight (for example, at the blade's tip) in order to achieve

desirable

inertial characteristics. At the leading edge, an (often metal) erosion shield

is used.

like fibreglass and carbon fibre are used for the

fabrication of rotorblades. Stainless steel leading edge spars are also used, and

all composite

spar designs exist too. The fatigue life properties of composite materials are far

better than those of metals. Fibreglass is used for its strength and chemical inertness.

Carbon fibre layers, sandwiched at right angles, are used to add stiffness. A sample design might look like the figure below. Generally, composite blades also

have some extra added weight (for example, at the blade's tip) in order to achieve

desirable

inertial characteristics. At the leading edge, an (often metal) erosion shield

is used.

When using modern composite materials, lightning strikes have to be considered because

these are more dangerous to composite constructions. This is because of the much greater electrical resistance of composite materials compared to all metal blades.

A lightning strike on composite materials produces a lot of heat along the current’s

path, which can damage the blade significantly. In order to provide a low resistance electrical path, the solution is to have

an outside skin that possesses low electrical

resistance and connects all of the rotor segments.

Comments are disabled.